Pour bénéficier d’un affichage optimal de la boutique en ligne de PanGas, vous avez besoin pour le navigateur de la version minimale suivante:

• Internet Explorer 9.0

• Mozilla Firefox 38

• Safari 8

• Chrome 45

Veuillez vous assurer que JavaScript est activé dans les paramètres de votre navigateur.

Food chilling

Building on many years of experience to deliver flexible cryogenic chilling innovations guaranteed to optimise results in even the most quality-critical mobile and stationary applications

Chilling needs vary significantly from one application to another. To ensure the best fit for your individual process flow, we have developed a variety of delivery systems and devices that bring the environmental and quality benefits of gaseous, liquid and solid (dry ice) cryogenic chilling agents to stationary and mobile applications.

Our ACCU-CHILL™ in-line chilling system, for instance, injects liquid carbon dioxide (LIC) or nitrogen (LIN) directly into mixing or storage vessels for instant results. We also have FROSTCRUISE™ in-transit refrigeration solutions based on LIN. If you need to transport smaller quantities, our SNOWCOOL™ isothermal trolleys rely on dry ice (or CO2 snow) for flexible temperature control. Dry ice can also optimise chilling at your conveyor or packaging station with our Dri-Pack chilling solutions. And if you need larger quantities of dry ice, our pelletiser systems can produce it on site for you.

To ensure precise temperature control and maximum efficiency when dosing dry ice, we have developed a range of standard CO2 expansion nozzles and snow horns. Regardless of whether you need a manual, portable or permanently integrated solution, all snow horns are designed to the highest industry hygiene standards and can be easily adapted to your individual chilling application.

ACCU-CHILL™ Dri-Pack systems FROSTCRUISE® SNOWCOOL® trolleys Snow horns

ACCU-CHILL™

Linde has an in-line chilling system called ACCU-CHILL™ . It is installed on blenders, mixers, tumblers, or batch vessels for the purpose of reducing the foodstuff temperature.

Linde’s ACCU-CHILL, better referred to as 'Bottom Injection,' reduces the temperature of the solid or liquid food products by injecting liquid carbon dioxide (LIC) or nitrogen (LIN) cryogens into the mixing or storage vessel. The cryogen is controlled by measuring several parameters, such as product viscosity, temperature and time to achieve desired temperature or product viscosity.

For example, meat customers will use ACCU-CHILL 'Bottom Injection' to achieve precise temperature control of products such as ground beef and chicken for the purpose of forming hamburger patties or nuggets.

Dri-Pack systems

The Linde Dri-Pack cooling system is the solution for processing industries where instant cooling of perishable products is used directly in the packing boxes.

The Linde Dri-Pack system is designed to automatically pour a predetermined amount of carbon dioxide snow into boxes of meat products or perishable products at low speed. The low application rate prevents overflow and the loss of carbon dioxide snow that often occurs with other designs.

These systems can be automatically or manually controlled on packaging lines with conveyors. The systems can be adapted to boxes of different sizes.

The main advantages are:

- Instant cooling

- Precise delivery of carbon dioxide into open boxes

- Easy to adapt to most conveyor belts

- Simple control

- Reduced labor costs

More information

FROSTCRUISE®: In-Transit Refrigeration

Getting the cold chain under control with an eco-friendly, low-noise, low-maintenance in-transit cryogenic refrigeration solution.

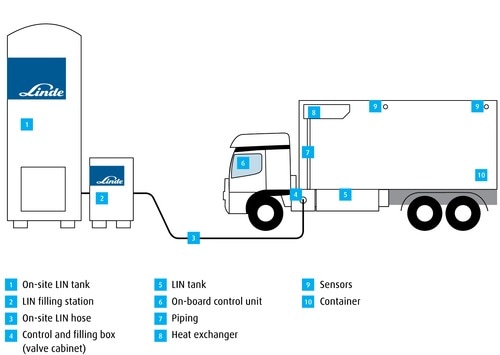

We developed our FROSTCRUISE® indirect cryogenic refrigeration system to meet the technical, cost and environmental pressures facing the trucking industry today. FROSTCRUISE is an efficient, economical, cryogenic replacement for mechanical, diesel-powered refrigeration units. Not only do mechanical units have a high carbon footprint due to diesel consumption, they are also relatively noisy, expensive to maintain and reliant on potentially harmful refrigerants.

FROSTCRUISE overcomes these environmental challenges by using liquid nitrogen (LIN) as the refrigerant. The LIN is stored at a temperature of -196°C in an insulated on-board tank. It is piped through a heat exchanger with a large surface area to release its cooling power. This causes the liquid nitrogen to evaporate and high-velocity fans circulate the cold air around the truck’s container.

More information

Highlights:

- Rapid cooling power with extremely stable temperature control

- Reduced carbon footprint through diesel savings

- Elimination of hazardous refrigerants (e. g. R404A)

- Low-noise design for easy deliveries at night time or to residential areas

- Longer service life compared with mechanical solutions

- Cost efficiencies due to ease of service and maintenance

- Reduced downtime – moving parts down to a single fan

- Image-building potential through active support for more sustainable transport options

SNOWCOOL®: Isothermal Trolleys

When you are challenged to manage a complex logistic supply chain with several product temperature specifications, maximise shipping coverage and minimise cost, you need a solution that can provide you the flexibility to achieve these competing needs

If reducing the risk of breaking the cold chain while maximising profits is your priority, then our SNOWCOOL® temperature control systems might be just what you have been looking for. It is a highly flexible and economic solution that uses dry ice snow, an extremely efficient and easy to use coolant.

SNOWCOOL trolleys provide the flexibility to deliver different temperature compartments within the same shipping environment, for example shipping fresh and frozen food products in the same vehicle. No matter if you have to transport fresh or frozen foodstuffs, the fully automated SNOWCOOL system always offers maximum protection through constant temperature control. Linde offers transport cooling via trolleys through the Snowcool application.

More information

Advantages:

- Fast and flexible

- Separate temperature profile for each container if required

- Deliver refrigerated foodstuff in non-refrigerated vehicles

- Inert atmosphere

- No chlorofluorocarbons (CFCs)

- Noiseless operation

- Low maintenance

- Low investment

Application and use:

- Insulated 'thermo containers' are used for the transport of temperature controlled foodstuffs in thermo containers, a snow box is installed for the intake of carbon dioxde snow

- Dosage is fully automatic and specified by presetting various parameters

- Foodstuffs remain at a stable temperature during transport

- This new cooling process offers a rapid supply of cooling energy in the form of carbon dioxide snow which is accurately measured to meet the required cooling demand

- The coolant can be supplied at any given time by withdrawal from a stationary carbon dioxide tank

- Special training is not required to operate the SNOWCOOL installation

- Insulated 'thermo containers' are used for the transport of temperature controlled foodstuffs in thermo containers, a snow box is installed for the intake of carbon dioxde snow

- Dosage is fully automatic and specified by presetting various parameters

- Foodstuffs remain at a stable temperature during transport

- This new cooling process offers a rapid supply of cooling energy in the form of carbon dioxide snow which is accurately measured to meet the required cooling demand

- The coolant can be supplied at any given time by withdrawal from a stationary carbon dioxide tank

- Special training is not required to operate the SNOWCOOL installation

Snow horns

Linde carbon dioxide snow horns provide a simple, cost effective method to accurately control temperature conditions in your chilling operations.

Snow horns are easily adaptable to most existing chilling systems. At the heart of Linde’s line of carbon dioxide snow generating equipment are Linde’s high and low velocity snow horns. Linde developed low and high velocity design snow horns to suit most conventional and hundreds of custom applications

More informatie

The unique 3.75 high velocity Snow Horn with its insulated stainless steel body is designed with an annular sub-cooling chamber and provides unparalleled efficiency in converting liquid carbon dioxide into snow. It is used in many cases to produce snow into closed containers such as a mixer or blender.

The Low Velocity Snow Horn (LVSH) series comes in both a 7 inch diameter and a 3.5 inch diameter model and is made of annodised aluminium or stainless steel. This horn is designed to provide a low velocity output of snow for placement in open containers such as boxes or bins without the spillage that would result from a high velocity horn.

Advantages:

- Easily adaptable to most mixing and blending equipment

- High and low velocity designs

- High refrigeration and chilling capacity in a small package

- Low capital cost

- Simple to install and easy to use

- Precise temperature control when combined with a Linde Chilling Control Panel